You are looking for a pair of sandals with a POM plastic buckle that is durable, strong, and abrasion resistant. Let's find out with Blog Shondo that POM plastic - a high-grade engineering plastic - is the secret behind this durability and flexibility.

1. What is POM plastic?

1.1. Definition

POM (Polyoxymethylene) plastic, also known as acetal or polyacetal, is a high-grade engineering thermoplastic. POM plastic is known for its high mechanical strength, good abrasion resistance and outstanding hardness, providing long-term use for products.

1.2. Development history

POM plastic was first discovered by chemist Hermann Staudinger in the 1920s. However, it was not until 1952 that DuPont succeeded in synthesizing and producing POM plastic commercially, marking an important turning point in the development of this engineering plastic.

1.3. Chemical structure

POM plastic has the chemical formula (CH2O)n, where n is the number of repeating units of the molecule. The molecular structure of POM plastic consists of long chains linked together by covalent bonds, creating a solid network structure, contributing to the hardness and durability of POM plastic.

1.4. Basic characteristics

POM plastic is usually opaque white or milky white, has a density of about 1.41-1.43 g/cm3 and a melting point of about 175-180 degrees Celsius. In addition, POM plastic also possesses many outstanding properties such as chemical resistance, good insulation, high tensile strength, hardness and good impact resistance, helping POM plastic to be widely used in many different fields.

[caption id="attachment_4914" align="aligncenter" width="800"] POM plastic is a high-grade engineering thermoplastic[/caption]

POM plastic is a high-grade engineering thermoplastic[/caption]

2. Advantages and disadvantages of POM plastic

2.1. Advantages

POM plastic possesses many outstanding advantages, making it an ideal material for many applications:

- High mechanical strength , good resistance to force and abrasion: POM plastic has tensile strength up to 70-80 MPa, compressive strength up to 110-120 MPa, much higher than common plastics such as ABS plastic (40-60 MPa), PP (30-40 MPa).

- Low coefficient of friction, self-lubricating ability: POM plastic has much better self-lubricating ability than other plastics such as Nylon, PA6 plastic , PTFE, helping to reduce friction and wear during use. This is especially useful for products that require smooth and durable movement such as gears and bearings.

- Dimensional stability, chemical resistance, insulation: POM plastic has high dimensional stability, little expansion or contraction during use. POM plastic also has good chemical resistance, especially organic chemicals, grease, and dilute acids. In addition, POM plastic is also a good insulating material, suitable for applications in the electronics industry.

- Easy to process and shape: POM plastic can be processed by conventional methods such as extrusion, injection molding, cutting... to create products with complex shapes and high precision.

2.2. Disadvantages

Besides the outstanding advantages, POM plastic also has some limitations:

- Poor resistance to acids, alkalis, and oxidants: POM plastic is easily decomposed in acidic, alkaline, or strong oxidant environments. Therefore, users should be careful to use POM plastic in suitable environments to ensure product durability.

- High thermal expansion rate, poor UV resistance: POM plastic has a higher thermal expansion rate than some other plastics, which can cause deformation in environments with sudden temperature changes. In addition, POM plastic is also susceptible to UV rays, which can cause aging and reduce product life.

- Limited operating temperature range , difficult to glue and paint: POM plastic has a fairly narrow operating temperature range, from -40°C to 100°C. In addition, POM plastic is also difficult to glue and paint, requiring the use of special glues and paints suitable for the properties of POM plastic.

Besides the outstanding advantages, POM plastic still has many advantages[/caption]

Besides the outstanding advantages, POM plastic still has many advantages[/caption]

3. POM plastic classification

3.1. Based on structure

POM plastic is classified based on structure into two main types:

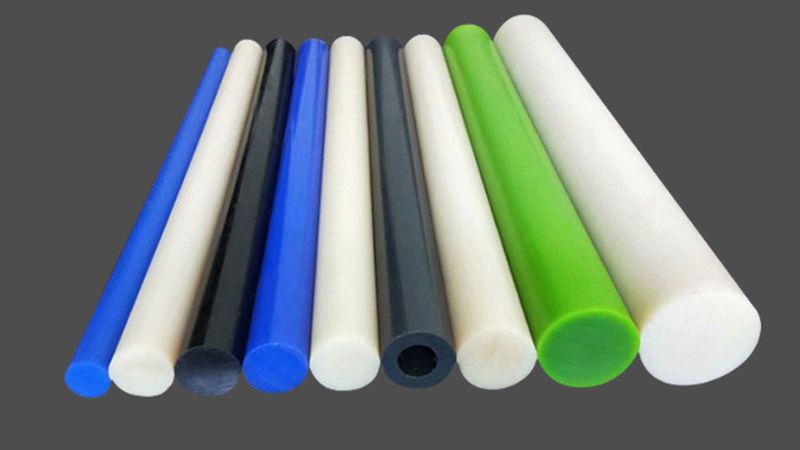

- POM plastic sheet: POM plastic sheet has common size of 1000mm x 2000mm, thickness from 3mm to 30mm. POM plastic sheet has the advantage of high hardness and bearing capacity, often used in applications requiring good hardness and bearing capacity.

- POM plastic rod: POM plastic rod has a cylindrical shape, diameter from 10mm to 100mm. POM plastic rod has the advantage of a smooth, glossy surface, high gloss, often used in applications requiring high aesthetics.

3.2. Based on characteristics

- Regular POM plastic: This is the most popular type of POM plastic, widely used in many fields.

- Anti-static POM plastic: This type of POM plastic is supplemented with anti-static agents to help minimize the accumulation of static charges, suitable for applications in the electronics industry and medical equipment manufacturing.

3.3. Based on color

POM plastic has many popular colors such as milky white, opaque white, black, gray, blue, red...

3.4. Based on quality

POM plastic is classified by quality into two main types:

- Type A POM plastic: This type of POM plastic has high density, uniform color, smooth surface, high quality, and is often used in applications requiring high precision and aesthetics.

- Type B POM plastic: This type of POM plastic has lower density, color may be uneven, surface may be slightly rough, lower quality, often used in general applications, less demanding on aesthetics.

POM plastic is classified based on different criteria[/caption]

POM plastic is classified based on different criteria[/caption]

4. Applications of POM plastic

POM plastic is a versatile material, widely used in many fields, from heavy industry to consumer goods.

- Transportation: POM plastic is used to manufacture fuel pump housings, control cables, wipers, gearbox gears, brake system components, etc. POM plastic provides high durability and good wear resistance, helping to improve the life and efficiency of these components.

- Industrial products: POM plastic is used to produce hoses, pumps, valves, components in water pipes, air pipes, etc. POM plastic helps these products have high durability, good corrosion resistance, ensuring safety and efficiency during use.

- Components, machinery: POM plastic is used to produce gears, bearings, bearings, engine parts, machinery, etc. POM plastic helps these parts operate smoothly, durably, minimizing friction and wear.

- Electronic products: POM plastic is used to produce gears, bearings, parts in electronic devices, etc. POM plastic has good insulation, effective anti-static, ensuring safety for electronic devices.

- Consumer products: POM plastic is used to produce toys, kitchen utensils, sports equipment, etc. POM plastic provides high durability and good impact resistance, making these products safe and durable during use.

- Medical: POM plastic is used to manufacture surgical instruments, medical equipment, etc. POM plastic has good antibacterial and anti-corrosion properties, ensuring hygiene and safety for medical instruments.

Not only that, POM plastic is used in fashion to produce sandal buckles thanks to its high hardness, good strength, abrasion resistance and high temperature resistance, bringing firmness and durability to the product. You can find the application of POM plastic in Shondo's fashion sandals, with beautiful design, high-quality materials, bringing a comfortable and durable experience to the user.

[caption id="attachment_4917" align="aligncenter" width="800"] Thanks to its outstanding advantages, POM plastic is widely used[/caption]

Thanks to its outstanding advantages, POM plastic is widely used[/caption]

5. Related questions

5.1. What temperature can POM plastic withstand?

POM plastic can withstand temperatures quite well, from about -40 degrees C to 140 degrees C. However, the exact temperature tolerance depends on the type of POM, POM-H has better heat resistance than POM-C.

5.2. Is POM plastic toxic?

POM plastic in solid state is safe for users. However, during the processing of POM plastic at high temperature, it is necessary to pay attention to the smoke and dust of POM plastic which can cause irritation.

5.3. Distinguish between POM plastic and ABS plastic?

POM plastic is harder, has better mechanical strength and abrasion resistance than ABS plastic. However, ABS plastic is cheaper and easier to process.

With outstanding advantages in durability, heat resistance, abrasion resistance and safety, POM plastic has been widely used in many industries, from the production of automotive components to fashion. Experience the durability and fashion of Shondo sandals with POM plastic zippers, bringing you comfort and style all day long!

Related Articles

Nếu bạn đã và đang sở hữu cho mình đôi giày ballet sneaker nhưng vẫn chưa biết outfit nào phù hợp. Xem ngay bài viết này với 5 cách phối đồ với giày ballet sneaker đẹp không có điểm trừ cùng Shondo...

Squid Game 3 chính thức khuấy đảo trên màn ảnh, bạn đã sẵn sàng ngồi liền 6 tập để xem cuộc chiến sinh tồn lần cuối của Gi-Hun chưa? Dưới đây là combo cuối tuần “chuẩn sinh tồn hiện đại” mà Shondo ...

Phong cách Retro là gì mà được nhiều người săn đón như vậy? Cùng Shondo tìm hiểu qua bài viết sau đây để biết thêm nhiều điều thú vị từ điểm đặc trưng cho đến cách phối đồ như thế nào là chuẩn nhé....

Một trong những trào lưu nổi bật gây sốt trên các cộng đồng yêu thời trang chính là phong cách Maillard. Nhưng điều gì khiến chúng lại có sức hút lớn đến như vậy? Shondo sẽ giúp bạn hiểu rõ hơn về...

Áo Polo nữ - item nghe thì tưởng già nhưng thực ra lại đang quay trở lại mạnh mẽ. Từ sân golf đến sân trường, từ văn phòng đến quán cafe, chiếc áo đơn giản với cổ bẻ đặc trưng này bỗng trở nên đa n...

Phối đồ Vintage trong giới thời trang mang đến những nét độc đáo rất riêng. Phong cách này trở thành xu hướng phổ biến không chỉ ở nữ mà còn xuất hiện nhiều ở nam giới. Shondo sẽ cho bạn thấy điều ...