PA6 (Nylon 6) plastic is a popular engineering plastic, widely used in many industries such as automobiles, electronics, ... and even in footwear production. So what is PA6 plastic ? This article will give you the most detailed look at this type of plastic, from properties, applications, advantages and disadvantages, comparison with PA66 and notes when using. Let's find out with Shondo right away!

1. Key Points

Useful information you will get after reading this article:

- This article provides an overview of PA6 plastic, including definition, history, properties and advantages and disadvantages.

- Visual comparison between PA6 and PA66 helps readers grasp the differences in properties and applications, thereby making the right choice for their needs.

- Share the application of PA6 plastic in the production of shoe eyelets, explain why PA6 plastic eyelets are popular and how to choose quality products.

- Answers to common questions about PA6 plastic such as heat resistance, toxicity and durability of shoe eyelets, helping readers to resolve common concerns.

2. What is PA6 plastic?

PA6 plastic, also known as Nylon 6, is a thermoplastic belonging to the Polyamide (PA) family, synthesized from caprolactam monomer. The reason for the name PA6 is because in the structure of this plastic, each repeating link contains 6 carbon atoms.

PA6 resin was invented by I.G. Schraker, who used a caprolactam as a raw material with γ-aminocaproic acid as an initiator. In 1939, the trial production of PA6 fiber was carried out and commercialized in 1943 by the German company Faben.

Currently, PA6 plastic is a popular and preferred engineering plastic in the Vietnamese market. With a mid-range price, PA6 plastic is widely used in many processing fields and industries that need to use plastic to replace other materials to reduce production costs.

[caption id="attachment_4813" align="aligncenter" width="800"] PA6 plastic is also known as Nylon 6[/caption]

PA6 plastic is also known as Nylon 6[/caption]

3. Characteristics of PA6 plastic

Advantage:

- High mechanical strength: PA6 plastic has good tensile strength, impact resistance, high surface hardness, and is resistant to deformation or breakage when subjected to force.

- Excellent wear resistance: Low coefficient of friction makes PA6 plastic effective in wear resistance, prolonging product life.

- Good heat resistance: PA6 plastic can operate in a wide temperature range, from -40 to 100°C, and can even withstand higher temperatures for short periods of time.

- Good dielectric properties: PA6 plastic has good electrical insulation, suitable for use in electrical and electronic applications.

- Chemical Resistance: PA6 plastic is resistant to a wide range of chemicals, greases and solvents.

- Easy to process: PA6 plastic can be easily processed by many different methods such as injection molding, extrusion, and film blowing.

- Reinforcement: The properties of PA6 resin can be improved by reinforcing with glass fibers or other fillers.

Disadvantages:

- Low dimensional stability: When affected by temperature and humidity, PA6 plastic can change size, causing difficulties for some applications that require high precision.

- Poor acid resistance: PA6 plastic is easily attacked by strong acids due to the presence of amide groups in its structure. When exposed to acids such as H₂SO₄, HCl or HNO₃, PA6 plastic is easily decomposed, reducing mechanical properties and durability.

Compared with common plastics such as PP (Polypropylene) or PE (Polyethylene), PA6 plastic is superior in terms of strength, abrasion resistance, heat resistance and insulation.

[caption id="attachment_4814" align="aligncenter" width="800"] PA6 plastic has good tensile strength and impact resistance[/caption]

PA6 plastic has good tensile strength and impact resistance[/caption]

4. Comparison of PA6 and PA66

PA6 and PA66 are both popular engineering plastics belonging to the Polyamide family, however, they have certain differences in structure, properties and applications. Below is a detailed comparison table of PA6 and PA66:

|

Criteria |

PA6 |

PA66 |

| Structure | Straight line | Straight chain, stronger hydrogen bonds than PA6 |

| Melting point | 220 - 230°C | 260 - 265°C |

| Tensile strength | Good | Very good |

| Hardness | Good | Very good |

| Impact resistant | Good | Very good |

| Abrasion resistant | Good | Very good |

| dehumidification | Medium | Lower than PA6 |

| Chemical resistance | Good | Very good |

| Application | Mechanical components, gears, textiles,... | Auto parts, electronics,... |

Overall: PA66 has many advantages over PA6 in terms of strength, hardness, heat resistance and chemical resistance. However, PA66 is more expensive and more difficult to process than PA6. The choice between PA6 and PA66 depends on the specific requirements of each application.

5. Applications of PA6 plastic in life

PA6 plastic with its superior properties has been widely applied in many areas of life, from heavy industries to daily consumer products.

In industry:

- Automobiles: PA6 plastic is used to manufacture parts in the engine system such as air ducts, air filters, fans, cable covers, etc. thanks to its heat resistance, grease resistance and high durability.

- Electronics: Electronic device housings, electronic components, LED bulbs are common applications of PA6 plastic in the electronics industry.

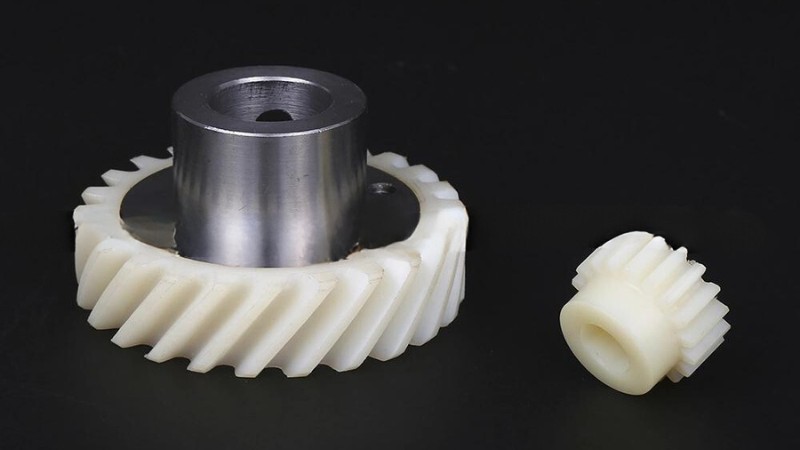

- Mechanical - manufacturing: Thanks to its hardness, durability and abrasion resistance, PA6 plastic is widely used in the production of machine parts such as gears, rollers, bearings,...

- Other industries: PA6 plastic is also used in the production of ropes, fishing nets, carpets, etc.

PA6 plastic used in gear manufacturing[/caption]

PA6 plastic used in gear manufacturing[/caption]

In life:

- Zippers, drawstrings: Durability, flexibility and good abrasion resistance make PA6 plastic an ideal material for manufacturing these products.

- Ropes, fishing nets: Good tensile strength and abrasion resistance help PA6 plastic products last in harsh environmental conditions.

- Shoe eyelets: PA6 plastic is increasingly popular in the production of shoe eyelets thanks to its high durability, tensile strength, good abrasion resistance, chemical resistance and skin friendliness.

Shondo shoe eyelets from PA6 plastic:

- Outstanding durability: Withstands pulling and strong pulling force, limits breakage and breakage, helping to increase product life.

- Anti-abrasion, chemical resistance: Helps the eyelets stay shiny, durable, and not oxidize or rust even when exposed to humid or chemical environments.

- Safe for users: PA6 plastic is a safe material, does not contain toxic substances, and is environmentally friendly.

PA6 plastic eyelets on Platy 2 beige bread sandals with moss [/caption]

PA6 plastic eyelets on Platy 2 beige bread sandals with moss [/caption]

6. Related questions

6.1. What temperature can PA6 plastic withstand?

PA6 plastic has good heat resistance, melting temperature is about 220 - 230°C. Under normal use conditions, PA6 plastic can withstand temperatures from -40 to 100°C. At higher temperatures, some properties of PA6 plastic may be affected.

6.2. Is PA6 plastic toxic?

PA6 plastic is a safe material, does not contain toxic substances such as BPA, formaldehyde,... and is certified safe for food contact by prestigious organizations around the world.

[caption id="attachment_4817" align="aligncenter" width="800"] PA6 plastic is a safe material[/caption]

PA6 plastic is a safe material[/caption]

6.3. Are shoes using PA6 plastic eyelets durable?

Shoes using PA6 plastic eyelets are often very durable, because PA6 plastic eyelets have many advantages:

- Good tensile strength: Helps prevent shoe eyelets from breaking or cracking when subjected to strong pulling force.

- Effective abrasion resistance: Helps keep shoe eyelets shiny, durable, and free of scratches or peeling during use.

- Chemical resistance: Helps prevent shoe eyelets from being corroded or oxidized by external agents such as rainwater, sweat, etc.

However, the durability of the shoe eyelets also depends on the quality of PA6 plastic and the manufacturer's production technology. Therefore, you should choose products from reputable, quality brands such as Shondo to ensure the durability and aesthetics of the product.

[caption id="attachment_4818" align="aligncenter" width="800"] Shoes using PA6 plastic eyelets are often very durable[/caption]

Shoes using PA6 plastic eyelets are often very durable[/caption]

PA6 plastic is a material with outstanding advantages in terms of durability, load-bearing capacity and safety. Shondo is proud to be a unit applying high-quality PA6 plastic, providing durable and beautiful shoe eyelets. Contact Shondo now to experience the best quality products and services!

Related Articles

Nếu bạn đã và đang sở hữu cho mình đôi giày ballet sneaker nhưng vẫn chưa biết outfit nào phù hợp. Xem ngay bài viết này với 5 cách phối đồ với giày ballet sneaker đẹp không có điểm trừ cùng Shondo...

Squid Game 3 chính thức khuấy đảo trên màn ảnh, bạn đã sẵn sàng ngồi liền 6 tập để xem cuộc chiến sinh tồn lần cuối của Gi-Hun chưa? Dưới đây là combo cuối tuần “chuẩn sinh tồn hiện đại” mà Shondo ...

Phong cách Retro là gì mà được nhiều người săn đón như vậy? Cùng Shondo tìm hiểu qua bài viết sau đây để biết thêm nhiều điều thú vị từ điểm đặc trưng cho đến cách phối đồ như thế nào là chuẩn nhé....

Một trong những trào lưu nổi bật gây sốt trên các cộng đồng yêu thời trang chính là phong cách Maillard. Nhưng điều gì khiến chúng lại có sức hút lớn đến như vậy? Shondo sẽ giúp bạn hiểu rõ hơn về...

Áo Polo nữ - item nghe thì tưởng già nhưng thực ra lại đang quay trở lại mạnh mẽ. Từ sân golf đến sân trường, từ văn phòng đến quán cafe, chiếc áo đơn giản với cổ bẻ đặc trưng này bỗng trở nên đa n...

Phối đồ Vintage trong giới thời trang mang đến những nét độc đáo rất riêng. Phong cách này trở thành xu hướng phổ biến không chỉ ở nữ mà còn xuất hiện nhiều ở nam giới. Shondo sẽ cho bạn thấy điều ...