In the context of the construction and manufacturing industry is constantly developing, finding durable, reasonably priced and easy-to-use materials becomes a top priority. PVC plastic emerges as an optimal solution, meeting all those criteria. So what exactly is PVC, let's find out with Shondo Blog in this article!

1. What is PVC plastic?

PVC, short for Polyvinyl chloride, is a popular thermoplastic widely used in modern life. This type of plastic is created from the polymerization reaction of vinyl chloride (VCM) molecules under the effect of pressure and temperature, forming long polymer chains.

Depending on the manufacturing method and additives, PVC exists in two main forms:

- PVC suspension (PVC.S): This is the most common form, accounting for about 80% of total global PVC production. PVC.S is in the form of white powder, mainly used in the production of molded and injection molded products such as water pipes, windows, floors, etc.

- PVC emulsion (PVC.E): This form has smaller particle size, forming a milky solution. PVC.E is often used in the production of paint, adhesives, medical gloves,...

In general, PVC plastic possesses many superior properties such as: high mechanical strength, good fire resistance, effective insulation and low production cost. In addition, original PVC is usually white, but can be mixed with a variety of colors according to usage needs.

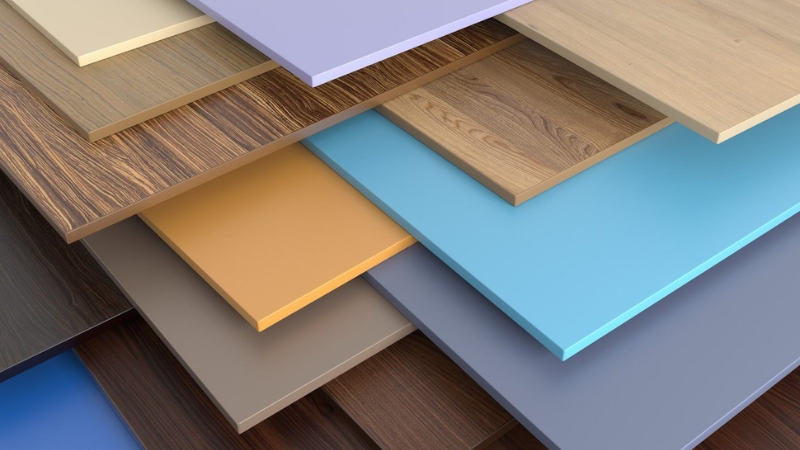

[caption id="attachment_4198" align="aligncenter" width="800"] PVC plastic possesses many outstanding superior properties[/caption]

PVC plastic possesses many outstanding superior properties[/caption]

2. PVC plastic classification

Based on properties and applications, PVC plastic is classified into 3 main types:

- Pure PVC (uPVC): 100% pure PVC, no plasticizers added, providing superior hardness, heat resistance, chemical corrosion resistance and excellent environmental impact. uPVC is the top choice for products requiring high durability such as water pipes, windows, doors.

- Rigid PVC: Contains about 5% plasticizer, making rigid PVC easier to process than uPVC but still ensuring the necessary hardness. This type is often used to produce electrical conduits, equipment covers, hard plastic panels, partitions, etc. with the advantages of good insulation and low cost.

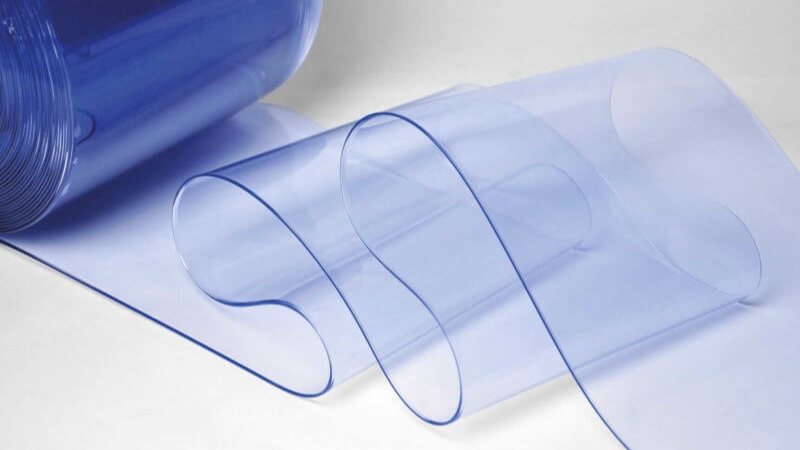

- Soft PVC: Contains a high proportion of plasticizers (20-70%), providing superior toughness, elasticity and flexibility. Soft PVC is widely used in the production of medical gloves, soft water pipes, food wrap, toys, etc. thanks to its safety and effective waterproofing and grease resistance.

Currently on the market there are 3 types of PVC plastic[/caption]

Currently on the market there are 3 types of PVC plastic[/caption]

3. Advantages and disadvantages of PVC plastic

PVC plastic has the following outstanding properties:

- Outstanding durability: PVC has high mechanical strength and resistance, good fire resistance. Even when exposed to high temperatures, PVC only melts but does not catch fire.

- Insulation ability: High resistivity makes PVC a safe insulating material, widely used in the electrical industry.

- Chemical corrosion resistance: PVC exhibits incredible chemical resistance, good corrosion resistance in harsh chemical environments such as electroplating and oil and gas.

- Easy to process: Its low density (1.5 - 1.7 g/m3) makes PVC easy to print and weld - a big advantage for the electronics industry.

- Environmentally friendly: PVC is easily recyclable and processed, contributing to reducing plastic waste and protecting the environment. PVC can be recycled into new products or converted into fuel.

PVC plastic is recyclable and easy to dispose of[/caption]

PVC plastic is recyclable and easy to dispose of[/caption]

4. Applications of PVC plastic in production and life

The applications of PVC plastic are extremely diverse, from industry to daily life, notably:

- In industry: PVC is widely used to prevent chemical corrosion in the electroplating, oil and gas, mechanical, welding industries, etc. thanks to its ability to withstand harsh environments.

- In construction: PVC is gradually replacing traditional materials such as wood, plaster, stone in applications such as wood-plastic flooring, wall and ceiling panels, etc. PVC scores points for its ability to resist moisture, dust, static electricity, high mechanical strength, bringing lasting beauty to the project.

- In interior design: With a diverse color palette and rich designs, PVC is the optimal choice for interior decoration applications for houses, offices, restaurants, hotels, boats, billboards, etc. PVC provides aesthetic solutions at reasonable costs, shortening construction time. Some popular applications include:

- In the fashion industry: PVC is present in the designs of sturdy, anti-slip shoe soles and unique labels and keychains, creating impressive highlights for sandals, slippers , sneakers, backpacks, etc.

F7R black beige men's and women's sandals [/caption]

F7R black beige men's and women's sandals [/caption]

5. Questions related to PVC plastic

5.1. Is PVC plastic safe for health?

Pure PVC is non-toxic. However, some additives added during the PVC manufacturing process, such as phthalate plasticizers, can be harmful to health if exposed for a long time.

Therefore, consumers should prioritize choosing PVC plastic products with clear origin, meeting quality standards, and inspected by authorities to ensure health safety.

[caption id="attachment_4202" align="aligncenter" width="800"] Should use PVC plastic with clear origin[/caption]

Should use PVC plastic with clear origin[/caption]

5.2. Can PVC plastic be recycled?

PVC plastic is recyclable, however, this process is not as easy as other types of plastic because PVC decomposes easily at high temperatures. PVC recycling requires careful sorting, removing impurities and using appropriate technology to avoid toxic emissions. However, PVC recycling is still highly recommended to reduce plastic waste and protect the environment.

[caption id="attachment_4203" align="aligncenter" width="800"] PVC plastic is recyclable[/caption]

PVC plastic is recyclable[/caption]

5.3. Distinguish between PVC and uPVC plastic?

uPVC (Unplasticized Polyvinyl Chloride) is a form of PVC plastic, supplemented with heat stabilizers and some other additives but does not contain plasticizers. Thanks to that, uPVC has the ability to withstand heat, impact resistance and higher durability than regular PVC. uPVC is often used in the production of water pipes, windows, doors,... while softer PVC is used to make food wraps, raincoats,...

In short, PVC plastic is one of the important and popular materials in the footwear manufacturing process with outstanding advantages such as superior durability, corrosion resistance and environmental friendliness. Don't forget to visit the website or shondo store to discover more models of sandals, sneakers, slippers, ... using quality PVC soles with youthful, fashionable designs!

Related Articles

Nếu bạn đã và đang sở hữu cho mình đôi giày ballet sneaker nhưng vẫn chưa biết outfit nào phù hợp. Xem ngay bài viết này với 5 cách phối đồ với giày ballet sneaker đẹp không có điểm trừ cùng Shondo...

Squid Game 3 chính thức khuấy đảo trên màn ảnh, bạn đã sẵn sàng ngồi liền 6 tập để xem cuộc chiến sinh tồn lần cuối của Gi-Hun chưa? Dưới đây là combo cuối tuần “chuẩn sinh tồn hiện đại” mà Shondo ...

Phong cách Retro là gì mà được nhiều người săn đón như vậy? Cùng Shondo tìm hiểu qua bài viết sau đây để biết thêm nhiều điều thú vị từ điểm đặc trưng cho đến cách phối đồ như thế nào là chuẩn nhé....

Một trong những trào lưu nổi bật gây sốt trên các cộng đồng yêu thời trang chính là phong cách Maillard. Nhưng điều gì khiến chúng lại có sức hút lớn đến như vậy? Shondo sẽ giúp bạn hiểu rõ hơn về...

Áo Polo nữ - item nghe thì tưởng già nhưng thực ra lại đang quay trở lại mạnh mẽ. Từ sân golf đến sân trường, từ văn phòng đến quán cafe, chiếc áo đơn giản với cổ bẻ đặc trưng này bỗng trở nên đa n...

Phối đồ Vintage trong giới thời trang mang đến những nét độc đáo rất riêng. Phong cách này trở thành xu hướng phổ biến không chỉ ở nữ mà còn xuất hiện nhiều ở nam giới. Shondo sẽ cho bạn thấy điều ...