In today's era, the need for printing is becoming more and more popular and diverse, from product printing, packaging, to advertising and fashion printing. To create quality printed products, besides the design factor, printing technology plays an extremely important role. In which, silk screen printing is one of the popular printing techniques and is widely applied in many fields. So what is silk screen printing ? What are the advantages and disadvantages of this printing technique? Let's find out the details with Blog Shondo through the article below.

1. Key Points

Useful information you will get after reading this article:

- Provides a detailed, easy-to-understand definition of screen printing, helping readers grasp the nature of this printing technique.

- Presents 6 basic steps in the screen printing process, from which readers understand the process of creating a complete screen printing product.

- Screen printing techniques are classified based on many criteria, helping readers have an overview and choose the technique that suits their needs.

- Introducing the application of screen printing in many fields, helping readers realize the popularity and potential of this printing technique.

- Answers to frequently asked questions about the durability, safety and care of screen printed products.

2. What is screen printing?

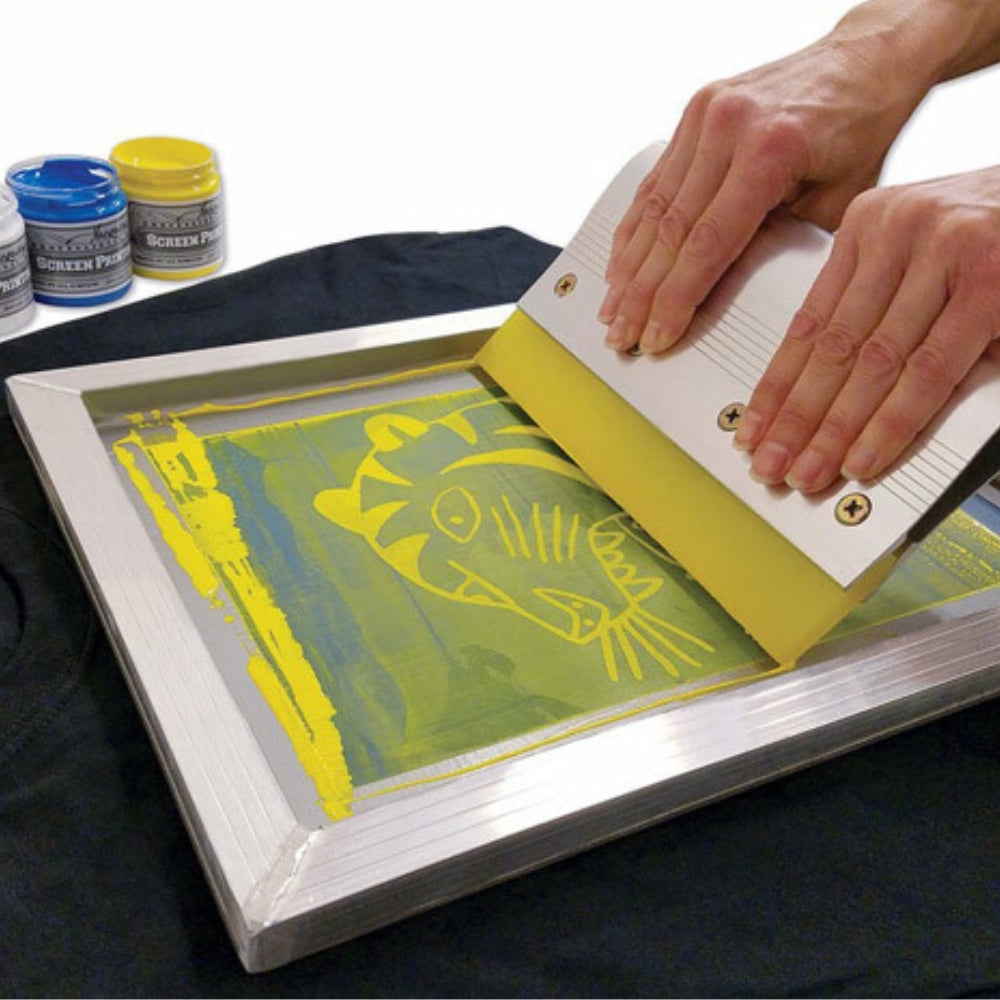

Screen printing is a printing technique that uses a screen made of silk fabric (nowadays it can be replaced by polyester fabric or metal mesh), the screen is pre-shaped with parts that allow ink to pass through and parts that do not. Then the ink will be spread evenly on the surface of the screen, absorbed through the mesh and printed on the surface of the material to be printed.

This printing method originated in ancient China and has undergone many improvements to become one of the most popular printing techniques today.

Unlike digital printing techniques that use inkjet printers directly onto the surface of the material, screen printing creates prints by forcing ink through a screen. This gives screen printing the advantage of color fastness and the ability to print on many different materials.

[caption id="attachment_5074" align="aligncenter" width="800"] Silkscreen printing of Shondo logo on Platy 5-ring black bread sandal [/caption]

Silkscreen printing of Shondo logo on Platy 5-ring black bread sandal [/caption]

3. Advantages & disadvantages of screen printing technology

3.1. Outstanding advantages of screen printing

- Low printing cost, suitable for everyone: Silk screen printing is a printing method with lower cost compared to modern printing techniques, especially suitable for large quantity printing needs.

- Printing on many materials: Screen printing allows printing on a variety of materials such as fabric, leather, wood, glass, metal, plastic, etc. to meet maximum product printing needs.

- Diverse colors, meeting all customer needs: Modern silk screen printing technology allows printing with a diverse color palette, meeting the strict color requirements of all customers.

- High color fastness, sharp images, no color fading: The printed product has high color fastness, sharp printed images, bright colors, and little color fading over time.

Modern screen printing technology allows printing with a diverse color palette[/caption]

Modern screen printing technology allows printing with a diverse color palette[/caption]

3.2. Disadvantages of screen printing

- Time consuming when printing multiple colors: For complex multi-color printed designs, the screen printing process will be more time consuming and labor intensive.

- Easy to make mistakes when using poor quality ink: The quality of ink directly affects the quality of printed products. If using poor quality ink, the printed image will easily become blurred, smudged, peeled,...

4. Professional screen printing process

4.1. Step 1: Prepare the printing plate

First, the printer will prepare the printing plate by stretching the fabric onto a wooden or metal frame. The frame material and fabric type will be selected to suit the size, shape and material of the product to be printed. Then, a special glue is mixed and a thin layer of glue is applied to the fabric surface to form a barrier, preventing the ink from seeping into unwanted areas.

4.2. Step 2: Take a film copy

The design file for printing will be processed and printed onto a transparent film. This film is called a film plate, and acts as a mask so that light only passes through the areas that need to be printed on the printing plate.

[caption id="attachment_5076" align="aligncenter" width="800"] Silk screen printing[/caption]

Silk screen printing[/caption]

4.3. Step 3: Mix the ink

Ink is mixed in a certain ratio, suitable for each printing material and desired color. Ink mixing requires precision and experience of the printer to ensure the color after printing is exactly as requested by the customer.

4.4. Step 4: Align the armrest and test print the product

After completion, the printing plate will be fixed on the printing table. The worker will adjust the support arm to determine the exact printing position on the product. Next, perform a test print on some sample products to check the print quality, color, sharpness, etc.

[caption id="attachment_5077" align="aligncenter" width="800"] Armrest, test print product[/caption]

Armrest, test print product[/caption]

4.5. Step 5: Batch printing

After the test print meets quality requirements, proceed to mass printing according to the quantity agreed with the customer.

4.6. Step 6: Cleaning the printing plate

After completing the printing process, the printing plate will be cleaned with specialized chemicals to completely remove any remaining ink and stored for use in the next printing.

[caption id="attachment_5078" align="aligncenter" width="800"] Cleaning the printing plate[/caption]

Cleaning the printing plate[/caption]

5. Popular screen printing techniques today

5.1. Based on the printing method

Depending on the production scale, productivity and accuracy requirements, the printer will choose the appropriate screen printing method. Specifically:

- Manual screen printing: This is a traditional printing method, using human power to operate in most stages. Manual screen printing has the advantage of low cost, suitable for printing small quantities. However, this method has the disadvantage of low productivity, difficult to uniform product quality.

- Semi-automatic screen printing: This method uses machines to support some steps such as ink wiping, lifting and lowering the printing plate,... to increase productivity and accuracy. Semi-automatic screen printing is suitable for printing medium and large quantities.

- Automatic screen printing: The entire printing process is performed automatically by modern machinery, providing high productivity, consistent and stable quality. Automatic screen printing is suitable for large-volume printing with high precision requirements.

Automatic screen printing system[/caption]

Automatic screen printing system[/caption]

5.2. Based on the shape of the printing plate

The shape of the printing plate is designed based on the shape and size of the product to be printed. The two most popular types of printing plates today are:

- Flat screen printing plate: This type of printing plate has a flat surface, suitable for printing on flat surfaces such as fabric, paper, plastic,...

- Round mesh screen printing plate: The printing plate is round in shape, often used to print on cylindrical items such as bottles, jars, cups, etc.

5.3. Based on printing method

Each printing technique will create different aesthetic effects for the product. Below are the 3 most popular printing methods:

- Direct screen printing: Ink is printed directly onto the surface of the material.

- Demountable screen printing: This technique creates raised patterns on the surface of the product using a specialized demountable glue.

- Screen Printing: This method uses a thin layer of glue to cover areas that are not to be printed, creating subtle gaps in the print.

Direct screen printing[/caption]

Direct screen printing[/caption]

6. Applications of screen printing in life

6.1. Fashion and garment industry

Screen printing is widely used in the fashion and garment industry to print logos, designs, slogans, etc. on products such as t-shirts, jackets, bags, hats , etc.

In particular, all Shondo products such as sandals , sneakers , and slides are applied with advanced silk printing methods, ensuring sharp, durable prints, enhancing the aesthetic value of the product. Shondo is proud to be a supplier of quality footwear products, applying modern printing technology, meeting the diverse needs of customers.

[caption id="attachment_5081" align="aligncenter" width="800"] Trendy 3 Doraemon full black cross-strap sandals with lovely Doraemon print[/caption]

Trendy 3 Doraemon full black cross-strap sandals with lovely Doraemon print[/caption]

6.2. Consumer goods manufacturing industry

Screen printing is also commonly used in the consumer goods manufacturing industry to print logos, images, and product information on products such as:

- Ceramic cups, glass cups

- Bottles, thermos

- Food containers

- Phone cases, covers

Screen printing application on phone cases[/caption]

Screen printing application on phone cases[/caption]

6.3. Printing and advertising industry

Screen printing is the optimal choice for printing products for the printing and advertising industry such as:

- Calendars, greeting cards

- Catalogue, brochure

- Flyers, posters

- Signs, banners

Silk-screened wedding invitations[/caption]

Silk-screened wedding invitations[/caption]

7. Related questions

7.1. Is screen printing durable?

The durability of screen printing depends on many factors such as:

- Ink quality: High quality ink will give durable, peel-resistant prints.

- Printing technique: Standard silk screen printing technique, performed by skilled printers will ensure the durability of the print.

- How to preserve: Preserving screen printed products properly, avoiding direct contact with high temperatures, chemicals, etc. also contributes to prolonging the life of the print.

Normally, silk screen printing has a fairly high durability, from 6 months to several years, even up to several decades if printed and preserved properly.

7.2. Is screen printing toxic?

Screen printing inks used today are mainly water-based inks, safe for users' health and environmentally friendly. However, some low-quality inks may contain toxic chemicals, affecting health. To ensure safety, you should choose reputable printing units, using high-quality inks with clear origins.

[caption id="attachment_5084" align="aligncenter" width="800"] Screen printing ink is mainly water-based, so it is safe for health[/caption]

Screen printing ink is mainly water-based, so it is safe for health[/caption]

Screen printing is a traditional printing technique with many outstanding advantages such as reasonable cost, diverse application capabilities and creating unique aesthetic effects. Hopefully, the article has provided you with useful knowledge about screen printing, from which you can choose the printing method that suits your needs.

Related Articles

Nếu bạn đã và đang sở hữu cho mình đôi giày ballet sneaker nhưng vẫn chưa biết outfit nào phù hợp. Xem ngay bài viết này với 5 cách phối đồ với giày ballet sneaker đẹp không có điểm trừ cùng Shondo...

Squid Game 3 chính thức khuấy đảo trên màn ảnh, bạn đã sẵn sàng ngồi liền 6 tập để xem cuộc chiến sinh tồn lần cuối của Gi-Hun chưa? Dưới đây là combo cuối tuần “chuẩn sinh tồn hiện đại” mà Shondo ...

Phong cách Retro là gì mà được nhiều người săn đón như vậy? Cùng Shondo tìm hiểu qua bài viết sau đây để biết thêm nhiều điều thú vị từ điểm đặc trưng cho đến cách phối đồ như thế nào là chuẩn nhé....

Một trong những trào lưu nổi bật gây sốt trên các cộng đồng yêu thời trang chính là phong cách Maillard. Nhưng điều gì khiến chúng lại có sức hút lớn đến như vậy? Shondo sẽ giúp bạn hiểu rõ hơn về...

Áo Polo nữ - item nghe thì tưởng già nhưng thực ra lại đang quay trở lại mạnh mẽ. Từ sân golf đến sân trường, từ văn phòng đến quán cafe, chiếc áo đơn giản với cổ bẻ đặc trưng này bỗng trở nên đa n...

Phối đồ Vintage trong giới thời trang mang đến những nét độc đáo rất riêng. Phong cách này trở thành xu hướng phổ biến không chỉ ở nữ mà còn xuất hiện nhiều ở nam giới. Shondo sẽ cho bạn thấy điều ...