Rubber is a highly elastic polymer material that can stretch and return to its original shape after being stretched or compressed. The origin of rubber can be natural or synthetic, meeting diverse needs in production and life. If you are still wondering what rubber is and what its properties and applications are, let's find out with Shondo Blog through the article below!

1. What is rubber?

Rubber is a highly elastic polymer that can be stretched many times its original length and return to its original shape when the force is removed. This material can be found in nature or created through chemical synthesis.

Classify:

- Natural rubber: Extracted from the latex of the rubber tree (Hevea brasiliensis), is a natural, environmentally friendly material source.

- Synthetic rubber: Made from petroleum and coal through complex chemical reactions.

Natural rubber is extracted from the latex of rubber trees[/caption]

Natural rubber is extracted from the latex of rubber trees[/caption]

2. History of formation and development of rubber

Rubber has been known and used by humans for centuries. The Mainas Indians of South America learned how to harvest the sap of rubber trees to create simple waterproof items.

The turning point for the rubber industry came in the 19th century, when Henry Wickham, a British explorer, brought rubber tree seeds from Brazil to plant in British colonies in Southeast Asia. This event opened the door to a large-scale rubber growing and production industry, meeting the world's growing demand.

Two important inventions that made rubber an indispensable material in modern life were Charles Goodyear's vulcanization technology (1839) and George Oenslager's method of accelerating the vulcanization process (1883). These inventions helped to significantly improve the properties of rubber, increasing its durability, hardness, and heat resistance.

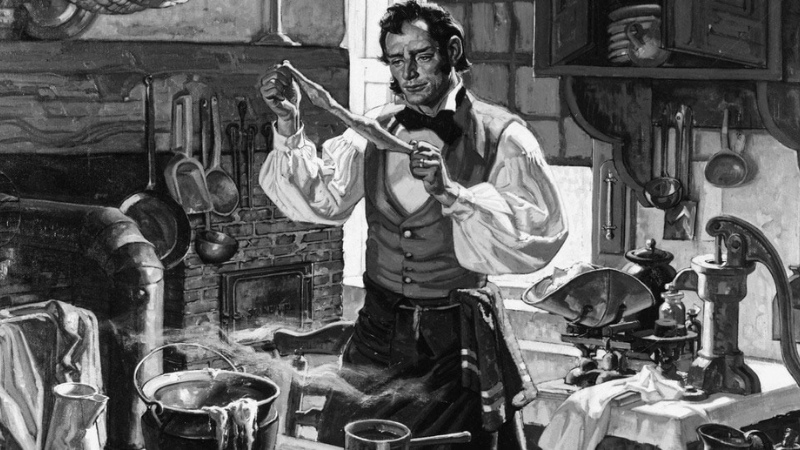

[caption id="attachment_2955" align="aligncenter" width="800"] Charles Goodyear invented vulcanized rubber[/caption]

Charles Goodyear invented vulcanized rubber[/caption]

The boom in the automobile industry in the early 20th century caused a surge in demand for rubber. However, the supply of natural rubber was not enough to meet the growing demand. Therefore, synthetic rubber was born as an effective alternative, with the ability to mass produce at a lower cost.

In Vietnam, rubber trees were introduced in the late 19th century and quickly became one of the country's important industrial crops. Through many stages of development, Vietnam has risen to become one of the world's leading rubber producing and exporting countries.

[caption id="attachment_2956" align="aligncenter" width="800"] Rubber has quickly become one of Vietnam's important industrial crops[/caption]

Rubber has quickly become one of Vietnam's important industrial crops[/caption]

3. Outstanding properties of rubber

Rubber possesses outstanding properties that make it an indispensable material in many areas of life and production:

- High elasticity: Rubber has incredible elasticity, can stretch many times its original size without permanent deformation.

- Good mechanical strength: Rubber can withstand tensile, tearing, abrasion and impact very well, ensuring product durability.

- Waterproof ability: Rubber is hydrophobic, preventing water from penetrating, suitable for creating waterproof products.

- Insulation: Rubber is a good insulator, does not allow electric current to pass through, ensuring safety in electrical applications.

- Vulcanization: The sulfur vulcanization process significantly improves the properties of rubber, increasing hardness, strength, heat resistance and chemical resistance.

Thanks to these superior properties, rubber (natural rubber and synthetic rubber) is widely used in the production of tires, footwear, medical products, construction materials and many other industries.

[caption id="attachment_2957" align="aligncenter" width="800"] High elasticity rubber[/caption]

High elasticity rubber[/caption]

4. Rubber classification

4.1. Natural rubber (NR)

Natural rubber, also known by the abbreviation NR (Natural Rubber), is a natural polymer with the chemical formula (C5H8)n. This type of rubber is extracted from the latex of rubber trees, mainly the Hevea brasiliensis rubber tree.

Advantages of natural rubber:

- Excellent elasticity: Rubber has excellent ability to restore its original shape.

- Safe and environmentally friendly: Natural material, biodegradable, less polluting to the environment.

- High durability: Withstands tensile, tearing, and abrasion well, prolonging product life.

Disadvantages of natural rubber:

- High cost: Depends on natural latex production, susceptible to fluctuations.

- Easily affected by weather: Rubber yield and quality depend heavily on weather conditions and pests.

- Limited supply: Depends on rubber tree planting area and yield.

Latex of rubber tree[/caption]

Latex of rubber tree[/caption]

4.2. Synthetic rubber (SR)

Synthetic rubber, abbreviated as SR (Synthetic Rubber), is created by chemical synthesis from petroleum and coal. This process involves polymerizing monomers (small molecules) to form long polymer chains, which are synthetic rubber.

Advantages of synthetic rubber:

- Versatile properties: Properties can be adjusted to suit a variety of applications.

- Lower cost than natural rubber: Helps reduce product manufacturing costs.

- Less affected by environmental factors: Raw materials and production processes are less dependent on natural conditions.

- Stable supply: Can be produced in large quantities to meet diverse market needs.

Disadvantages of synthetic rubber:

- Strength and elasticity may be less than natural rubber.

- The manufacturing process can cause environmental pollution.

Synthetic rubber (SR)[/caption]

Synthetic rubber (SR)[/caption]

There are many different types of synthetic rubber on the market today, each with its own characteristics, for example:

- Styrene-Butadiene Rubber (SBR): The most common type, widely used in tire manufacturing, due to its high abrasion resistance and durability.

- Polybutadiene Rubber (BR): Has good elasticity, often used as an additive for other types of rubber to increase toughness.

- Butyl Rubber (IIR): Good gas permeability, used in the production of tire tubes and medical gloves.

- Ethylene-Propylene-Diene Rubber (EPDM): Withstands high temperatures and weather effects, used in the production of gaskets, seals, and pipes.

Butyl Rubber (IIR)[/caption]

Butyl Rubber (IIR)[/caption]

5. Rubber production process

5.1. Natural rubber production process

- Step 1- Harvesting latex: People cut the rubber tree bark to collect latex. Latex, also known as rubber latex, is a milky white liquid that flows from the bark.

- Step 2 - Latex processing: The latex will be filtered to remove impurities. Then, acid is added to coagulate the latex into a solid form.

- Step 3 - Forming: The coagulated latex is fed into a rolling mill to form sheets or blocks of the required thickness.

- Step 4 - Drying: The rubber sheets or blocks are dried by smoking or heat drying to remove any remaining water.

The first step is to harvest the rubber tree latex[/caption]

The first step is to harvest the rubber tree latex[/caption]

5.2. Synthetic rubber production process

- Step 1 - Polymerization: Monomers are polymerized together in certain proportions in chemical reactors to form synthetic rubber.

- Step 2 - Processing: The synthetic rubber is processed to remove impurities and solvents.

- Step 3 - Finished product processing: Finally, rubber is processed into different product forms to meet usage needs.

Raw synthetic rubber[/caption]

Raw synthetic rubber[/caption]

6. Applications of rubber in life and production

Rubber is an essential material in many fields, playing an important role in modern life:

- Tire manufacturing: This is the most common application of rubber. High durability, good abrasion resistance and elasticity help tires grip the road well, absorb shock and ensure safety during operation.

- Footwear production: Rubber is used to make soles of shoes, sandals, boots, etc., providing comfort, anti-slip, durability and aesthetics to the product.

- Medical industry: Medical gloves, tubes, bottle caps,... made from rubber ensure hygiene, isolation, and safety for users.

- Construction field: Rubber is used as waterproofing material for roofs, walls, floors; soundproofing for karaoke rooms, cinemas; insulation for pipes,...

- Industry: Conveyor belts, gaskets, seals, pipes,... made from rubber that can withstand friction, temperature, and chemicals, meeting the needs of operating in harsh industrial environments.

In addition, rubber is also used in many other fields such as manufacturing toys, sports equipment, electronic equipment, etc.

[caption id="attachment_2963" align="aligncenter" width="800"] F7R beige and blue school sandals for men and women with anti-slip rubber sole[/caption]

F7R beige and blue school sandals for men and women with anti-slip rubber sole[/caption]

7. Rubber materials in footwear production

In the footwear industry, rubber is an indispensable material, especially in the product lines of fashion footwear and sports footwear. The reason why rubber is popular in footwear production is due to its outstanding advantages:

- High durability: Rubber soles have good abrasion resistance, do not deform when subjected to impact, helping to prolong the product's life.

- Anti-slip: The rubber surface has good adhesion, helping users move safely on many different terrains, even when the surface is wet.

- Soft and comfortable: The elasticity of rubber helps reduce shock, creating a soft feeling for the wearer, allowing comfortable movement for long periods of time.

- Easy to shape and color: Rubber can be easily shaped into many unique shoe sole designs and can be dyed in a variety of colors to meet the aesthetic needs of consumers.

Trendy 4 bread slippers T7M brown beige [/caption]

Trendy 4 bread slippers T7M brown beige [/caption]

Some common types of rubber used in footwear production include vulcanized rubber, SBR synthetic rubber, EVA synthetic rubber, etc. Each type of rubber will have its own characteristics, suitable for each type of footwear and different purposes.

If you are looking for a pair of sandals with rubber soles, you can refer to some sandal models with soles combining quality phylon and rubber materials at shondo: F8M beige moss men's and women's sandals , F6S beige blue men's and women's school sandals , F8B black and white high-sole men's and women's sandals ,...

[caption id="attachment_2966" align="aligncenter" width="800"] F6S men's and women's school sandals with gray sole and black combination [/caption]

F6S men's and women's school sandals with gray sole and black combination [/caption]

8. Frequently asked questions about rubber

8.1. Is rubber toxic?

Natural rubber is inherently non-toxic and safe for users. However, some synthetic rubbers may contain additives that can cause skin irritation for people with sensitive skin.

Our advice is to carefully check the product ingredients before purchasing and using. You should prioritize choosing products with clear origins, manufactured by reputable brands.

8.2. How to distinguish between natural rubber and synthetic rubber?

You can distinguish between natural rubber and synthetic rubber based on the following criteria:

- Origin: Natural rubber is extracted from the latex of rubber trees, while synthetic rubber is created from petroleum.

- Properties: Natural rubber generally has better elasticity and mechanical strength than synthetic rubber.

- Cost: Synthetic rubber is usually cheaper than natural rubber.

- Environmental Impact: Natural rubber is a more environmentally friendly material due to its biodegradability.

Natural rubber usually has better elasticity[/caption]

Natural rubber usually has better elasticity[/caption]

8.3. How to best preserve rubber products?

To prolong the life of rubber products, you should note the following:

- Store in a cool, dry place: Avoid exposing the product to direct sunlight or high heat sources, especially natural rubber products, because they are susceptible to aging and loss of elasticity.

- Clean the product regularly: Use a damp cloth to wipe away dust and dirt on the product surface. Do not use strong detergents as they can wear out and reduce the product's lifespan.

- Store shoes in a box: With shoes made of rubber, you should clean them after each use, dry them naturally and store them in a box when not in use.

Store shoes in boxes[/caption]

Store shoes in boxes[/caption]

In short, rubber is an important and indispensable material in modern life, contributing to improving the quality of human life. Come to Shondo to experience durable, comfortable and safe footwear products, created from high-quality rubber materials, combined with modern production technology.

Related Articles

Nếu bạn đã và đang sở hữu cho mình đôi giày ballet sneaker nhưng vẫn chưa biết outfit nào phù hợp. Xem ngay bài viết này với 5 cách phối đồ với giày ballet sneaker đẹp không có điểm trừ cùng Shondo...

Squid Game 3 chính thức khuấy đảo trên màn ảnh, bạn đã sẵn sàng ngồi liền 6 tập để xem cuộc chiến sinh tồn lần cuối của Gi-Hun chưa? Dưới đây là combo cuối tuần “chuẩn sinh tồn hiện đại” mà Shondo ...

Phong cách Retro là gì mà được nhiều người săn đón như vậy? Cùng Shondo tìm hiểu qua bài viết sau đây để biết thêm nhiều điều thú vị từ điểm đặc trưng cho đến cách phối đồ như thế nào là chuẩn nhé....

Một trong những trào lưu nổi bật gây sốt trên các cộng đồng yêu thời trang chính là phong cách Maillard. Nhưng điều gì khiến chúng lại có sức hút lớn đến như vậy? Shondo sẽ giúp bạn hiểu rõ hơn về...

Áo Polo nữ - item nghe thì tưởng già nhưng thực ra lại đang quay trở lại mạnh mẽ. Từ sân golf đến sân trường, từ văn phòng đến quán cafe, chiếc áo đơn giản với cổ bẻ đặc trưng này bỗng trở nên đa n...

Phối đồ Vintage trong giới thời trang mang đến những nét độc đáo rất riêng. Phong cách này trở thành xu hướng phổ biến không chỉ ở nữ mà còn xuất hiện nhiều ở nam giới. Shondo sẽ cho bạn thấy điều ...